UL Door

90 / 120 / 180

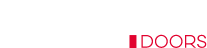

Solution for high traffic areas

ASTURMADI's UL fire door was specially tested to meet the most demanding requirements according to American ANSI - NFPA standards with 120 minutes resistance and reaching a maximum classification in 180' in both single and double leaves and required in a multitude of projects around the world.

Wide range of standard sizes in two different heights for greater "economization" in projects, resulting in high quality at a good price.

Special measures to adapt it to any need.

Thermal Insulation Coefficient 1.2 (W/m2k)

Superior torsional stiffness of the blade versus traditional assembly.

Highly corrosion resistant and durable sheet metal and paint.

Open frame for easy installation.

Excellent standard equipment.

Wide range of extra accessories available.

Tested for more than 200,000 opening and closing cycles.

Approved as a whole.

Required in many international markets in Asia, Africa and the Americas

90, 120 and 180 minutes fire resistance with marking AINSI UL 10C

Galvanized steel sheet between 0.7 and 0.9 mm. thick, assembled by roll forming machine by double folding and stitching of the LID-BOX assembly.

Rock wool insulation density 145/180 Kg/m3.

Galvanized steel stiffeners.

Anti-lever bolt in steel, hexagonal 14x36 mm. zinc-plated.

Blade thickness 51 mm.

Approximate weight of 25/29 Kg/m2.

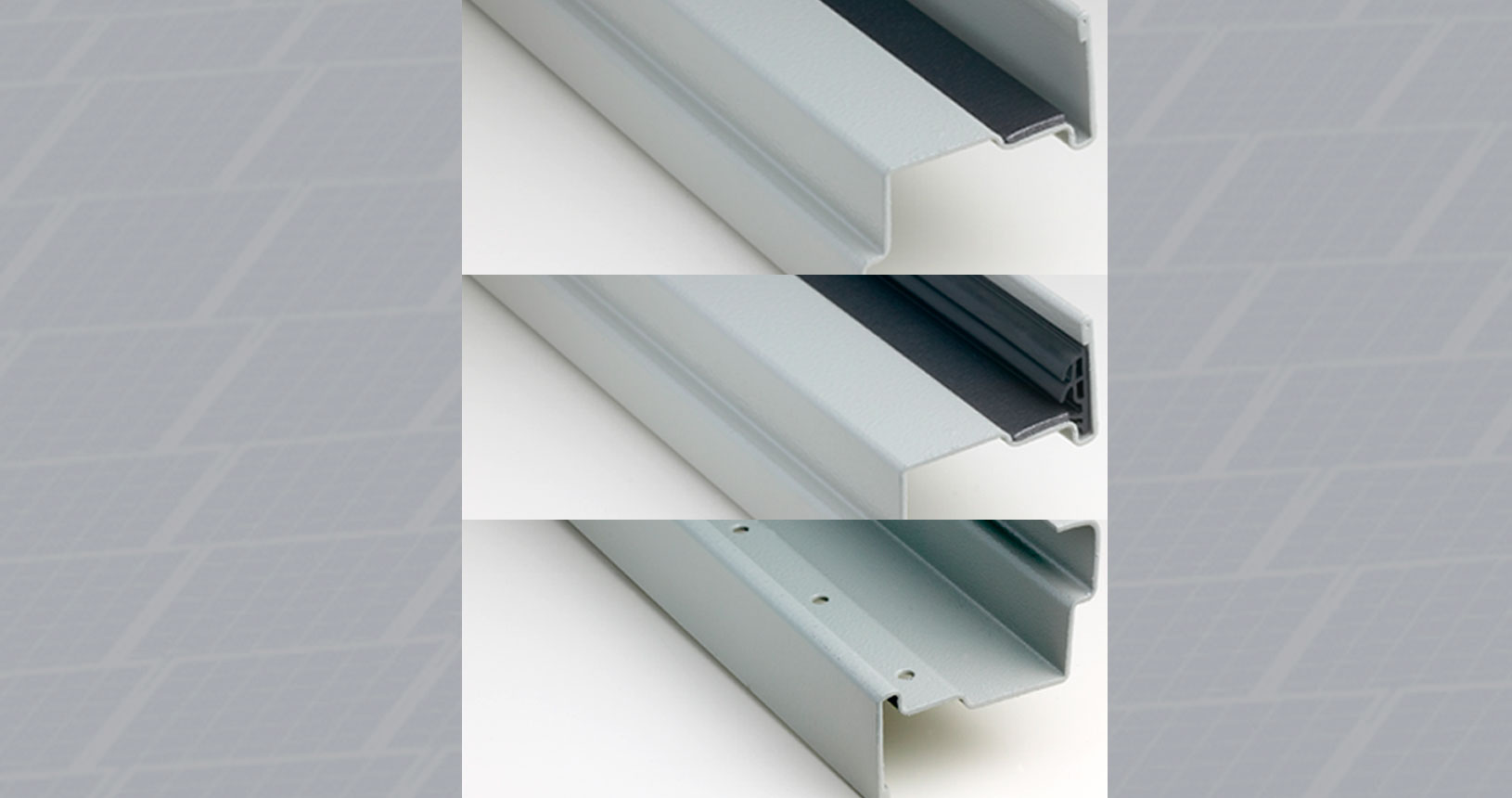

Steel with reduced thermal conductivity, 1.5 mm thick.

Jambs and lintels of the special profile ASTURMADI model Z-shaped.

Cold rolled steel clamping claws, 230 x 1.5 mm..., for different types of partition walls.

Steel plate spacers 50 x 2.5 mm.

ANTIBACTERIAL thermosetting epoxy powder painted plate (additivated with silver nitrate).

Paint coating of 100 microns on the sheet, and 120 microns on the frame.

Complete RAL color chart.

3 mm thick steel hinges fixed to the leaf with zinc-plated M6x16 screws, and to the frame by welding, the lower hinge being semi-automatic locking torsion hinge.

Graphite intumescent gasket 15 x 2 mm. It expands 25 times its size at Tª > 150ºC.

Reversible CF lock with double locking bolt, embedded in the leaf, protected by two MO stucal plates.

Sintered steel latch.

Brass bulbs, 40 x 40 with 3 keys.

Anti-lever pin.

UL approval label.

Handle

Model CF anti-snagging.

With fusion-lined steel core.

Metal shields lined with nylon and hardware.